Pune, June 25, 2025 (GLOBE NEWSWIRE) -- Artificial Intelligence in Manufacturing Market Size Analysis:

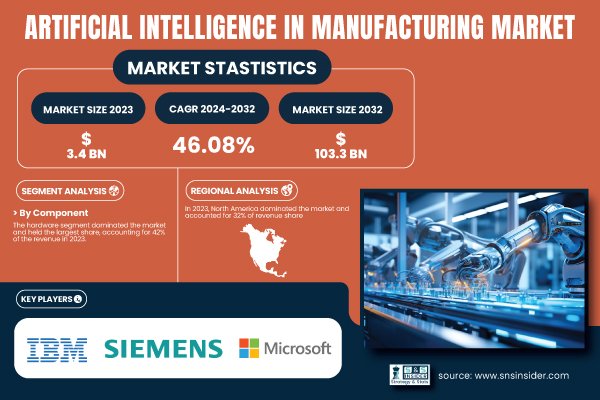

“The SNS Insider report indicates Artificial Intelligence in Manufacturing Market size was valued at USD 3.4 billion in 2023 and is estimated to reach USD 103.3 billion by 2032, growing at a CAGR of 46.08% during the forecast period of 2024–2032.”

In 2023, the U.S. market was valued at approximately USD 0.8 billion and is projected to reach USD 23.9 billion by 2032, growing at a CAGR of around 45.73% from 2024 to 2032. Growth is fueled by Industry 4.0 adoption, a skilled AI workforce, and heavy investment in smart factory initiatives.

Get a Sample Report of Artificial Intelligence in Manufacturing Market@ https://www.snsinsider.com/sample-request/6587

Major Players Analysis Listed in this Report are:

- IBM Corporation – Watson IoT for Manufacturing

- Siemens AG – Industrial Edge

- Microsoft Corporation – Azure AI

- Alphabet Inc. (Google Cloud) – Vertex AI

- Amazon Web Services (AWS) – AWS IoT SiteWise

- General Electric Company (GE Digital) – Predix Platform

- SAP SE – SAP Digital Manufacturing Cloud

- Oracle Corporation – Oracle AI for Manufacturing

- Rockwell Automation, Inc. – FactoryTalk Analytics

- NVIDIA Corporation – NVIDIA Metropolis for Factories

- Intel Corporation – Intel Edge AI Software

- Schneider Electric SE – EcoStruxure Machine Advisor

- PTC Inc. – ThingWorx Industrial IoT Platform

- Fanuc Corporation – FIELD system (Fanuc Intelligent Edge Link and Drive)

- ABB Ltd. – ABB Ability™ Genix Industrial Analytics and AI Suite

Artificial Intelligence in Manufacturing Market Report Scope:

| Report Attributes | Details |

| Market Size in 2023 | US$ 3.4 Billion |

| Market Size by 2032 | US$ 103.3 Billion |

| CAGR | CAGR of 46.08 % From 2024 to 2032 |

| Base Year | 2023 |

| Forecast Period | 2024-2032 |

| Historical Data | 2020-2022 |

| Key Segments | • By Component (Hardware, Software, Services) • By Application (Material Movement, Predictive Maintenance & Machinery Inspection, Production Planning, Field Services, Quality Control & Reclamation, Others) • By Technology (Machine Learning (ML), Computer Vision, Context Awareness, Natural Language Processing) • By End-Use (Semiconductor & Electronics, Energy & Power, Medical Devices, Automobile, Heavy Metal & Machine Manufacturing, Others) |

| Key Growth Drivers | AI is being adopted to boost efficiency, cut costs, and enable smarter, faster manufacturing decisions. |

Do you have any specific queries or need any customization research on Artificial Intelligence in Manufacturing Market, Make an Enquiry Now@ https://www.snsinsider.com/enquiry/6587

By Component: Hardware Leads the Market, Software Grows Fastest with Cloud Integration and AI-as-a-Service

The hardware segment dominated the market and held the largest share, accounting for 42% of the revenue in 2023, attributable to the high demand for AI-enabled devices such as smart sensors, edge devices, and embedded chips in manufacturing equipment. Such elements, which can be considered as the hardware part of smart factories, allow data to be processed locally and in real-time. The hardware deployment is also driven by the increased investments in robotics, automated material handling, and industrial cameras. The need for hardware is fundamental to manufacturing because more companies are leaning toward cyber-physical systems that rely upon effective utilization of AI.

The software segment is expected to register the fastest CAGR, as cloud-native platforms, AI-as-a-Service models, and ongoing innovations in algorithms for machine learning support it. Manufacturers are now using software tools for predictive analytics, digital twins, production planning, and anomaly detection, for example. Demand for flexible, subscription-based software platforms that can easily scale AI models and integrate with ERP and MES systems is driving innovation.

By Application: Production Planning Dominates While Predictive Maintenance & Machinery Inspection Gains Traction

In 2023, the production planning segment held the largest market revenue share in the market, due to the use of AI in real-time decision-making, demand forecasting, and optimizing resources. AI helps manufacturers by keeping track of inventories, creating an optimal sequence of workflows, and scheduling production in an effective manner to reduce waste. With the help of AI-powered simulation tools and digital twins, the scenarios are modeled, and production cycles can then use aleatory with adaptive allocation of resources.

The predictive maintenance and machinery inspection is projected to witness the fastest growth, as there is a rise in demand to reduce unplanned downtime and increase machine life. AI allows for the identification of faults at an early stage, real-time diagnostics, and performance trends detection. Manufacturers now use IoT sensors and machine learning to predict failures in advance and automate maintenance schedules, which in turn saves downtime costs and enhances safety.

By Technology: Machine Learning Leads, Computer Vision to Grow Fastest with Visual Quality Control

The machine learning segment dominated the market and accounted for 34% of revenue share in 2023, as it enables pattern recognition, process optimization, and intelligent decision-making from large datasets. It is instrumental in studying machine dynamics, configuring production lines, and optimizing asset usage. Elevate it to the cloud and integrate it with functions from supply chain to production, making it the foundation of AI-enabled manufacturing ecosystems.

Computer vision is expected to grow at the fastest rate due to the usage of defect detection, fine inspection, and method automation. Manufacturers are blending vision systems with AI for micro-defect detection, assembly line precision and compliance. Now that visual data has become easily available and cameras are cheap, computer vision is at the core of any automated visual intelligence on the factory floor.

By End-Use: Medical Devices Dominate While Automobile Segment Grows Fastest with Smart Production

The medical device segment dominated the market in 2023 and accounted for a significant revenue share, due to stringent quality standards, precision requirements, and regulatory compliance. The third application for AI is to automate cleanroom processes and enhance traceability, while ensuring precision manufacturing. By combining digital twins and process analytics, manufacturers can achieve rapid prototyping and rapidly meet increasingly complex healthcare needs.

The automobile sector is projected to register the fastest CAGR due to an increase in the integration of AI with vehicle assembly, quality control, and supply chain processes. AI enables automatic welding, painting, and inspecting parts, improving consistency and throughput. AI-powered flexible manufacturing is the competitive edge in a world where there is a growing shift from petrol cars to electric and driverless cars.

Buy an Enterprise-User PDF of Artificial Intelligence in Manufacturing Market Analysis & Outlook 2024-2032@ https://www.snsinsider.com/checkout/6587

By Region: North America Leads While Asia-Pacific Emerges as Fastest Growing Market

Due to the presence of strong technological infrastructure, early adoption of Industry 4.0, and enormous investments by major players in manufacturing, North America led the market with 32% of revenue share in 2023. North America, being the pioneer of AI robotics, edge computing, and software platforms integrated with smart factory models, Major players in the U.S.

Rapid industrialization, the smart manufacturing initiative by governments, and increasing AI adoption among emerging economies such as China, India, and South Korea will fuel APAC's dominance during the forecast period, with the fastest CAGR. Artificial intelligence is being integrated into the electronics and automotive industries in the region for predicting maintenance needs, quality inspection, and flexible production systems.

About Us:

SNS Insider is one of the leading market research and consulting agencies that dominates the market research industry globally. Our company's aim is to give clients the knowledge they require in order to function in changing circumstances. In order to give you current, accurate market data, consumer insights, and opinions so that you can make decisions with confidence, we employ a variety of techniques, including surveys, video talks, and focus groups around the world.